Mazak Ace Manual

Ace 150. Ace 250 2 peak signal area. With practice at pinpointing, you will be able to pinpoint objects very quickly. Five MODE options—Like the ACE 150, the ACE 250 has All-Metal, Jewelry and Coins modes. The ACE 250, however, has two additional modes: Custom and Relics. CUSTOM Mode—This Mode can be. Mazak’s UD-400/5X has won the Main Prize at the “One of the Best 10 Products in Japan in 2017” Awards, held by Nikkan Kogyo Shimbun Ltd. MORE Today manufacturers everywhere face many challenges - constantly striving to reduce production costs, increasing the use of automation, a growing shortage of skilled employees among many others.

I'm trying to jump into programs on my M2 controller after tool changes so I don't have to rerun the entire program to finish bore a hole at the end. I'm using ISO programming because that's what I know and I'd rather not have to learn Mazatrol.

I've got a pretty long program and both my boss and I would like for me to be able to jump into the program at certain points in the program. I'm trying to use the restart function but am having trouble getting it to let me run the program.

The last time I tried restarting the program I input 300 (the number of the line of code right after my optional program stop (M01)) when it asked for the sequence number to restart, 1 for the block number (because that's what the guys at Mazak told me to do after entering 0 threw an illegal data input alarm), and 1 for the subprogram repeat number. It now throws alarm number 328-DESIGNATED SNO. NOT FOUND ( 35 300 1960 ). The 300 maybe due to the block number I'm trying to start on and the 1960 probably has something to do with my program because that's my program number.

I looked that up in the Operators Manual and it said 'In the program restart function, a specified tool sequence number (TSNO) was not found in the unit with a specified unit number (UNO) of the program with a specified work number (WNO).' I've tried my program number as the sequence number before and my block number as the block number before.

Where do I go from here? Does anybody have any idea how to do this with an M2?

The guys at Mazak said the oldest controller they have on hand is an M32 and what they've told me to do works on their end but not on mine. Anybody know more than Mazak? It might not be that hard to exceed their knowledge at this point. Between losing a board and a battery, I had to reinstall my parameters (M32B).

I seem to have everything back to working, except the tool probe. I can go to MDI, and select Auto and tell it which tool to touch off, and everything goes fine, but the XY location that the machine positions itself to is no longer over the tool probe.

I have gone thru my parameters very carefully and cannot find anything out of place, I have been thru the books I have and nowhere can I find a procedure to reset this location. Any help appreciated! We have a '94 QT15 with a T2 control (our favorite little workhorse) in the shop. It's a champ.Lately, it's been throwing a 20 NMI EMERGENCY STOP error code when we power it up in the morning. It will eventually reset (1-4 hours later), but I can't have that sort of down time everyday.I've tried the OT Release while resetting. We've checked and re-seated all the boards and connections. We've reinitialized the control.

We've even had Mazak send a guy out to fix it.Nobody knows what to do (including Mazak's tech, at the cost of a few months worth of downtime:wall: ).Does anybody have any input? Possible fixes? Even a simple copy of an electrical manual would help.Thanks in advance! Dear fellowsI recently aquired an mazak ace manual lathe. The first thing that struck me on this machine is that the electrical motor have a direct start- there is no star/delta or softstart system- and it pulls around 63Ampere on startup (3phase,230v). In regards to this i was wondering if other users have experienced this, and how was it solved?The second thing, is the wirebrake on the motor, in order to rapidly stop the chuck from rotating there is a mechanical brakesystem.

I want to get rid of this and was thinking about building an electrical brake- by changing the wiring to the motor in order to slow it down- so how about this guys, any thoughts or doable solutions?The third thing is documentation and manuals for the machine- unfortunately the local agent have only some gearbox documentation, i have also looked through the net without luck. I would like to have a user and service manual.Thanks for taking the time to respond.

I have simple little thing that I want to do that seems like it should be done using the shape data and CPY process. I can't make it work. A picture of the part is below. It is a 2' shaft with a 3' od shaft collar welded to it. It is to be a driver to drive some bushings out on a bulldozer.

I want to face off and chamfer the 2' shaft and turn the collar down from 3' od to 2.48' od. Program pictures shown below It is giving me a '319 Illegal Material Shape OD' error. I assume my material shape data is wrong but the programming manual does not have any examples. What am I doing wrong? Mazak QTN 200 msy with matrix control, want to know when using mazatrol if there is a way to call up a tool (like a drill thats been indicated in) in MDI and go to X0 Y0 so i can double check center or check a tool thats already in the machine? Very simple on a fanuc control, but not sure how mazatrol picks up the tool set and offset?

And what about double holders? Is there a code? I tried using the tool change soft key on the MDI page and then G0 X0 Y0 but it don't pick up the Y offset that is in the wear offset(don't have a geometry tool set for Y)I was looking at the eia manual and there is a list for tool data, so I tryed this in MDI T0101.01 XOYO and it worked (the.01 is for id number A-.02 for B ect).but only for single tool holders, we use some double holders, I also noticed if I have multiple tools (the same but with diff. Codes A,B,C,D, ect) for the same staion on the turret you can not use TEACH on X for centering drills ect. It jumps back to the first one in the list? Have to write it down from the pos.

Screen, X from the MACHINE numbers. And Y from the POS.

So if I want to check and make sure its on center I have to bring it down to the numbers with the handle, cant do it in MDI, what a joke. And if you have multiple tools in tool data, you better make sure your on the one you want when using the tool eye, it jumps to the first one in the tool data also. I guess mazak is not set up for using double tool holders, you can do it, but what a pain, maybe there is parameters somewhere to deal with this? Any help would be great. I just cant get use to the tool data crap, fanuc has got e'm beat bad! T0101 T0111 T0121 T0131 or what ever you want soooo simple. Sdrdx software defined radio sdr app for mac. Hello,Setting up our 2014 VCU 400 with a Matrix control.

More than likely setting the M16 parameter is no different than any other Matrix control. The B and C axis are off more than I like so resetting them. The problem is that the settings are real touchy, move one way, one result, move another a different, most of the inputs just run out the available travel, about 5 or 6 degrees.

The math is 25.4 x the degree off by, I guess metric.I am missing something, you should be able to home it, manually move it to the home position with dial indicator, multiply degree reading by 25.4, input to M16 the difference, turn off he machine until boards lose power, all in 'expert mode', what am IA missing, Mazak said that should not be happening??? Hello,Mike here.I have a Mazak SQT 10MS (1994).Recently, I have notice that there is a 'clicking' noise coming from the turret area when the turret indexes.Normally I do not hear it if it only indexs one tool. But, if I index more than one tool 3,4,5,6,7,8, etc. I get a clicking noise.It is not real loud, but you can certainly hear it when standing at the machine. It is hard to tell, but it sounds like it is in same timingas tooling as it rotates. In other words, one click for each tool that passes.

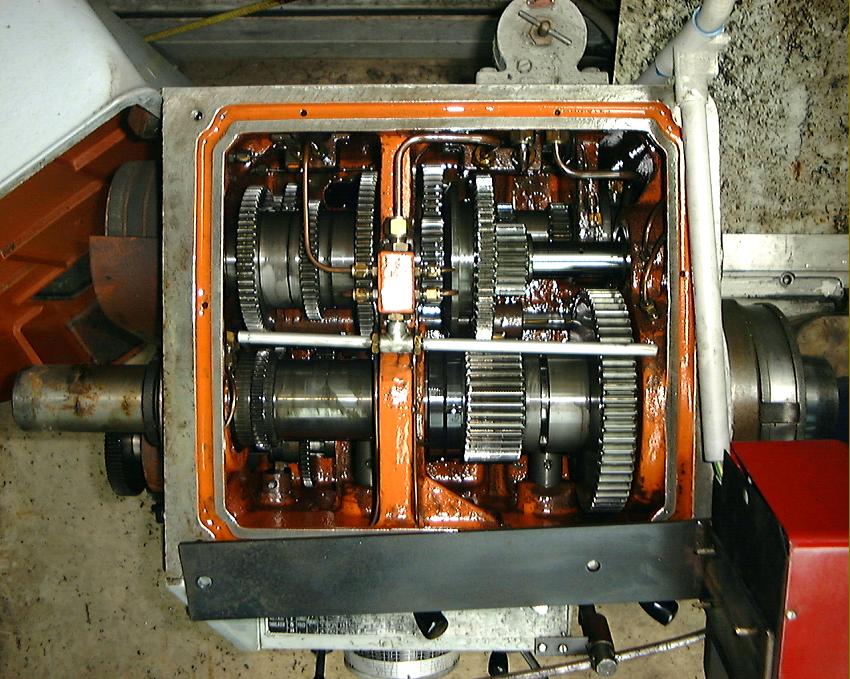

It is hard to tell.So, I have run a few hundred parts on it this way. I am just about complete with a job and I want to have a look and was wondering if anyone hasany experience with such an issue? What to look for?I jump up on back of the machine and look between the covers down behind the turret with a flashlight. It is very hard to see down in there.But, I see what I believe is s large gear directly behind the turret. It must be 8-10' in diameter.

I think this is the gear that is drivenby a hydraulic motor (I can not see the hydraulic motor shaft from this angle). It seems like the noise is coming from that area, but it is hard to tell.Is it possible that the gear has damage that I am hearing that? But, it if were that large gear, it seems like I would only hear the noise once every fullrevolution (assuming damage only in one spot).

But, I believe I hear a click for every tool that passes. So like 12 times per full revolution.Or, is something rubbing on this gear creating a clicking noise?

Any ideas and suggestions would be great!As a side note.anyone have an idea of how to grease these gears that are buried behind the turret??I think it is time to put on the tool belt and dive in to have a look. Not a fun area to get to.Thanks in advance.Mike. Hey guys.I'm in the process of looking at an sqt15ms with a t plus controller, and while i can easily program a basic 2 axis program to test cutting etc, i have no idea on the c axis and live tooling programming side of things.What I'm hoping someone can hook me up with is a simple program that will test it all.

Obviously I'll have to change dimensions and tooling etc in the program, but it will just save me working out what i need to input while I'm trying to test the machine.Cheers,TravSent from my LG-H815 using Tapatalk. I purchased a mazak nexus 100-II and it appears that something is missing in the far back left corner of the machining compartment.

I took a couple photos and in the one, a drill is pointing to the hole.The back of the machine is too clean to have been open plus you can feel/see that sealant used to be on the joint.I've looked in the manuals and came up blank so far. Anyone know what might be missing?I was thinking second light but I don't think they would have put it there.

There is one above where a tailstock usually goes (not equipped with ts). I can transfer programs fine in Tape mode, using my Calmotion USB box. I can DNC fine, the first time I run it.

But, lets say I need to DNC a program 5 times. I should be able to cancel the last transfer on the Calmotion, and set everything back up just like I did to run it the first time.

But, this does not work. I notice that on the command page, instead of the '.' in work number spot, It has the last DNC program in it. I cannot find a way to restart the DNC process, so I end up shutting off the control, power up /rehome and then go to tape mode and it runs it just fine, once.It seems like it is stuck, I have an 'm30' and a '%' at the end of my G-code. I think it is a control issue but I am all ears! Hi,is there any way to include a g-code into the mazatrol programm or at least put them both into a cycle? I want to use that cycles for bar pulling.

But the thing is i want to attach the bar puller on the cut-off blade holder. So i want it to do the following:1. Making a part2. Change tool for cut-off3.

Cutting off the part4. After the cut-off, spindle stops and the x-axis moves forward for the barpuller to grab the bar piece.5. Then chuck unclamps and the Z-axis moves with the bar piece for a desired length6. X-axis moves backward and goes for the tool change for start the programm7.

The programm starts againJust like on that video.

Mike Lynch

Founder and President, CNC Concepts Inc.

Read Next

Many machining centers, especially horizontal machining centers, come with a two-pallet pallet changing system. The operator loads one pallet while the other is in cycle. It is quite important, of course, that when the operator activates the cycle, the correct pallet is in the machine. A mistake in this regard can be disastrous.

Unfortunately, most machine tool builders provide little in the way of pallet confirmation. Again, if the wrong pallet is in the machine, the control will simply activate the program, ignoring the problem.

If your machine has parametric programming capabilities, it is quite easy to add your own pallet confirmation system.

We're showing an example in Fanuc's custom macro B, but with a little ingenuity, you should be able to apply this technique with just about any version of parametric programming.

We'll use a #500 series permanent common variable with which to store the current pallet location. We'll make #501 = 1 if pallet A is in position and #501 = 2 if pallet B is in position. #501 is a permanent variable. Like an offset, its value will be retained even after the power is turned off.

With custom macro B, the function of your pallet change activation word (commonly a M60) can be changed to automatically update the value of #501 with each pallet change. (See below.) A test can be made at the beginning of each program to confirm that the correct pallet is in position before allowing machining to occur.

Note that this is a software solution to the problem, and the control could get mixed up if the program is stopped in the middle of a pallet change.

A more positive (but much more difficult) method would be to use the #1000 series input signal terminals in conjunction with physical limit switches mounted on the pallet changer to determine which pallet is in position.

However, here is the 'easy way,' using #501 as a flag to determine which pallet is in position.

You must first manually set the value of #501 (just like you set an offset) to initially specify which pallet is in position. You'll find #501on the variables page of your display screen. If pallet A is currently in position, manually set #501 to 1.0. If pallet B is currently in position, set #501 to 2.0.

With custom macro B, a parameter must be set to make the control activate a specific program (O9001 in our case) whenever an M60 is activated. You must reference the custom macro descriptions in the programming manual for your specific control to confirm the parameter number. For a 16M Fanuc control, for example, it is parameter number 6071.

You must set this parameter to a value that corresponds to your pallet changing M code. If your pallet changer is activated with a M60, set this parameter to a value of 60. From this point, whenever the control reads an M60, it will execute program O9001.

Next, you must load program O9001 into your control.

O9001 (Pallet changing program—control will execute this program when M60 is read)

M60 (Normal pallet change command)

IF [#501 EQ 1] GOTO 1 (IF pallet A WAS in position GOTO N1)

#501 = 1 (If pallet B WAS in position, set #501 to 1, pallet A now in position) GOTO 2 (Skip N1)

N1 #501 = 2 (Set #501 to 2 - pallet B now in position)

N2 M99 (Return to calling program)

Now, in every program that requires the correct pallet to be in position, add the following commands at the very beginning.

If pallet A is supposed to be in position:

O0001 (Pallet A is supposed to be in position right now!)

IF [#501 EQ 1] GOTO 1

#3000 = 100 (WRONG PALLET IN POSITION)

N1 (Normal commands in program)

If pallet B is supposed to be in position:

O0001 (Pallet B is supposed to be in position right now!)

IF [#501 EQ 2] GOTO 1

#3000 = 100 (WRONG PALLET IN POSITION)

N1 (Normal commands in program)

The #3000 system variable will, if activated, put the machine into an alarm state (if all is okay, the control will skip this command). The message MC-100 WRONG PALLET IN POSTION will appear on the display screen.